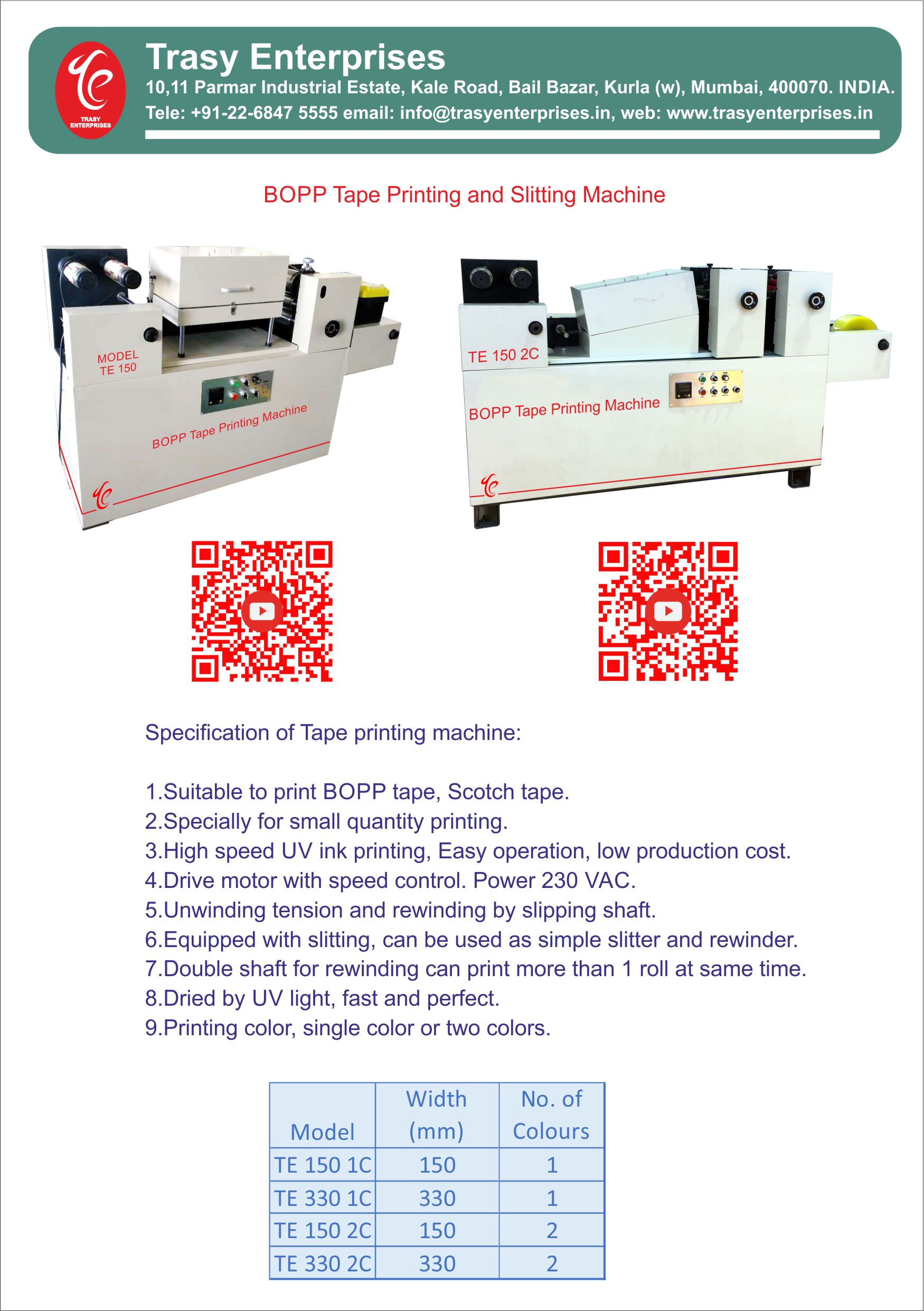

BOPP Adhesive Tape Printing: In the case of the adhesive tape printing it is printed almost exclusively with Gravure printing technology and the critical factor is the volume of the order. For large quantities of BOPP adhesive tapes, the BOPP is first printed on a jumbo roll without adhesive. On the printed foil on the side of the printing is then applied the adhesive. Therefore, this technology is also called inter-layer pressure or sandwich-pressure, as the ink is between the BOPP and the adhesive. For smaller volumes of BOPP, the material is already prefabricated (adhesive is already applied) and it´s cut into small rolls. The material is then printed and cut to the final size of the tape. This time the ink is applied on the adhesive surface. The advantage of this process is the printed mater is scratch proof and glossy. Printed with Flexo technology so the plate making cost is less and fast. The disadvantages of this method is only can print on transparent tapes. No colour or patch or multicolour design is possible. We feel this will be very good machine for micro scale business.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry