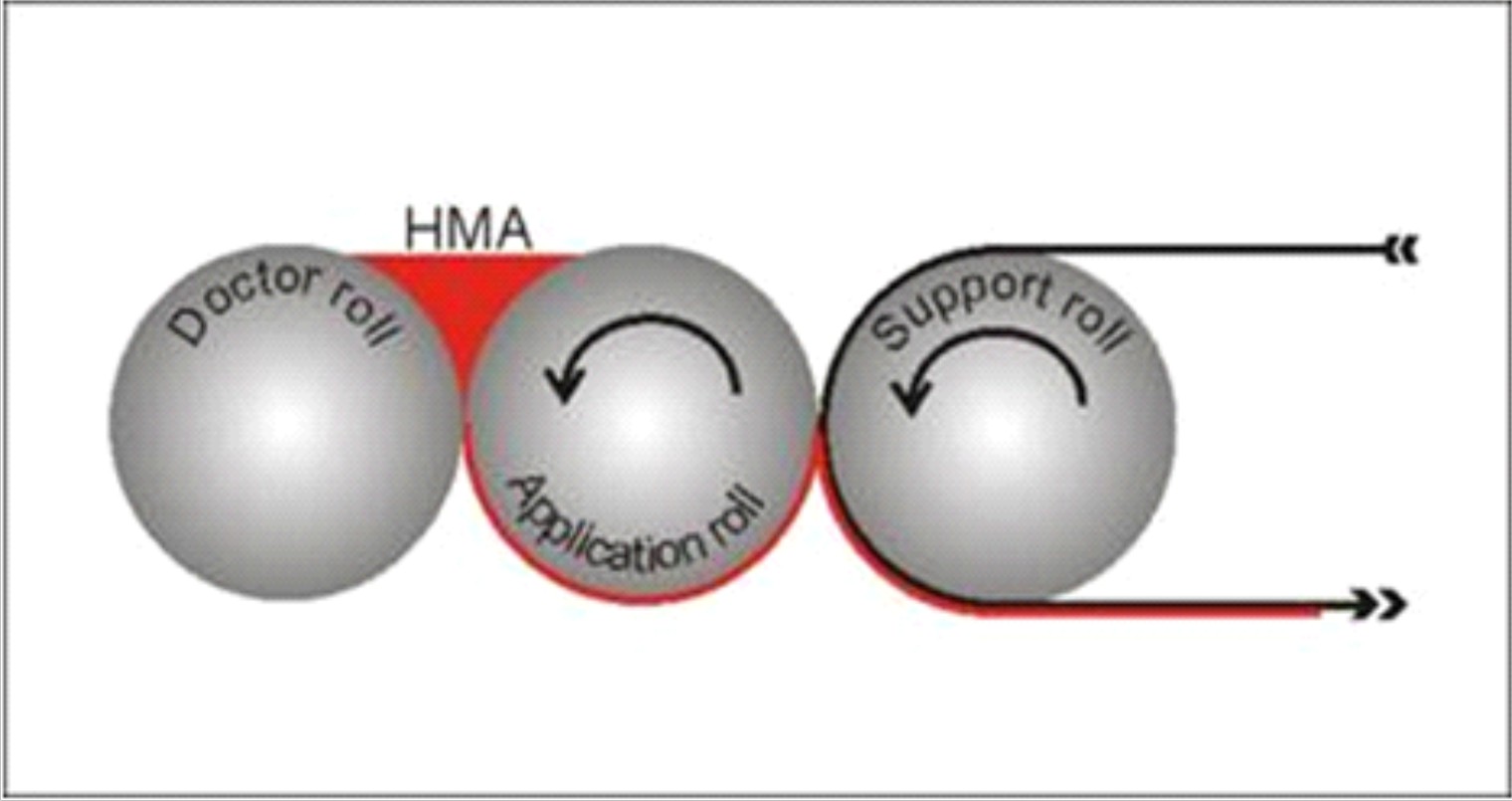

Reverse Roll Hot Melt Coating: What is it? What is reverse roll hotmelt coating? Well, put simply reverse roll coating is a cost-effective and relatively easier method for Hot Melt coating applications. A Reverse Roll Coating mechanism consists of a doctoring roll, a substrate in contact with it, and a roll to load material on in contact with the substrate (Consult the diagram). The hot melt is released between the doctoring roll and substrate that forms a kind of reservoir between the 2, as the substrate rolls, it keeps collecting the adhesive on its surface. Cloth coating, stretch bandage coating, etc. are products that use the reverse roll coating mechanism. This process, however, has its limitations. For one it cannot be used for high-speed mass production as it cannot exceed speeds of 10-15 m/minute, Sometimes the coating roller gives fumes due to high temperatures of the roller and thin layer of the adhesive on the roller hence the hot melt degrades due to high temperatures and loses its sticking property, therefore, anything below 25 GSM does not get coated evenly on the material.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry